Fresenius Medical Care & Daniels Health Partnership: A Case Study

In 2022, Daniels Health entered a partnership in select markets with the nation’s leading dialysis service provider, Fresenius Medical Care (“FMC”). FMC was seeking to expand its national relationship with various medical waste haulers and chose Daniels Health as one of their significant partners to achieve this objective.

Our internal teams collaborated with FMC’s leadership to develop a robust, long-term implementation plan that would manage the incremental rollout of Daniels’ waste management solutions while ensuring minimal disruption to FMC’s continuum of care, both local and system wide. In addition to a seamless ongoing roll-out, we have developed a standardized, sustainable waste management program with reporting benchmarks that drives ongoing and trackable results, including reduced labor & service requirements, and a decrease in waste volumes and disposal costs.

leadership to develop a robust, long-term implementation plan that would manage the incremental rollout of Daniels’ waste management solutions while ensuring minimal disruption to FMC’s continuum of care, both local and system wide. In addition to a seamless ongoing roll-out, we have developed a standardized, sustainable waste management program with reporting benchmarks that drives ongoing and trackable results, including reduced labor & service requirements, and a decrease in waste volumes and disposal costs.

This partnership with FMC was successful thanks to an initial trial program that enabled Daniels to demonstrate its ability to deliver on expectations with measurable results. The pilot program developed at FMC presents a replicable model for how to evaluate waste management vendors across complex health systems.

THIS CASE STUDY WILL REVIEW:

- Pre-Daniels State

- Sharpsmart & Regulated Medical Waste Trial

- Onboarding & Implementation

- Standardized National Reporting

- Results with Daniels

Facing challenges with their existing medical waste services, FMC approached Daniels in November 2020 for a formal request for information (RFI). FMC was seeking a more integrated management solution that delivered a higher standard of safety and compliance, a stronger service guarantee with forward-planning contingencies, and, ultimately, a long-term strategic partnership. Moreover, FMC was looking for a partner to provide robust, consistent, and transparent data reporting to monitor success and drive program efficiency.

All together, FMC was seeking a partner to address the following:

- Service issues, such as missed pickups, poor communication, and inventory shortages

- A containment system with stronger safety features and higher end-user satisfaction

- Optimization of fill rates and service frequencies

- High cost of service

- Diversification of waste vendor services

In March 2021, Daniels executed a pilot across 21 sites in Florida, which included the rollout of the safety-engineered Sharpsmart system and reusable RMW bins. In a controlled geographical segment, the pilot enabled Daniels to demonstrate its ability to deliver a safety and service excellence standard that exceeded industry norms.

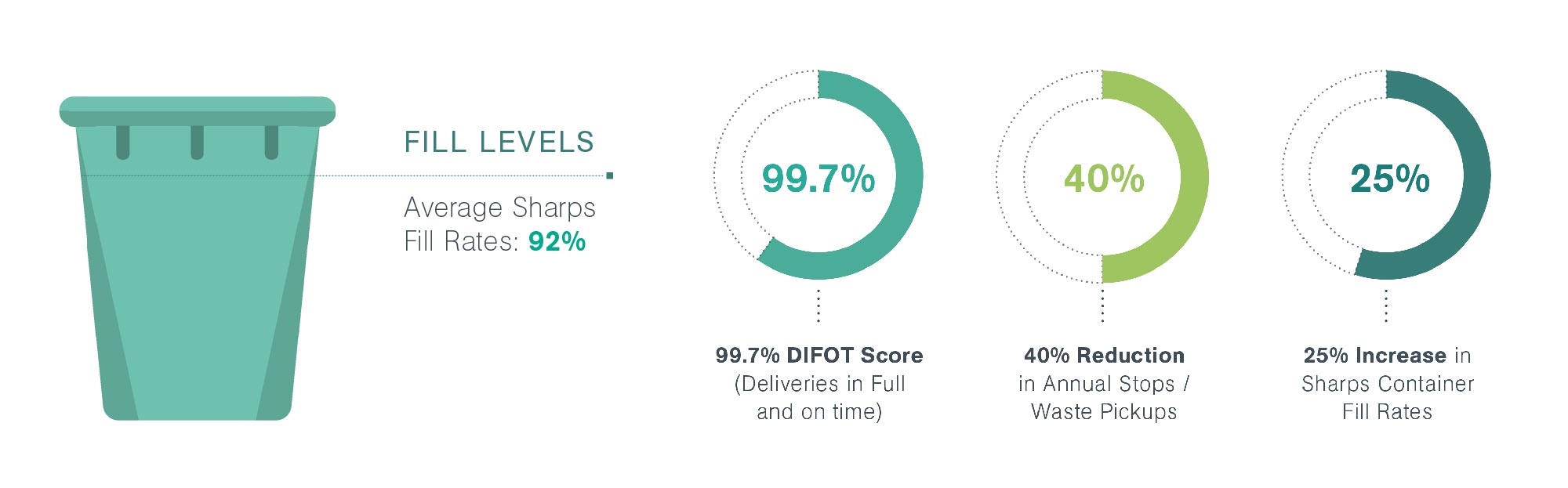

The results of this trial delivered:

- Seamless Onboarding + Implementation

- Zero Missed Pick-Ups

- 40% Reduction in Annual Stops

- 25% Increase in Sharps Container Fill Rates

Following the successful trial, Daniels was awarded the first 300 FMC clinics in May 2022 (locations in Florida, Minnesota, Wisconsin, and Michigan). Daniels’ implementation plan would ensure 20 installed locations per month (a pace consistent with FMC’s change-appetite and concerns over potential business disruption). Since contract execution, Daniels has exceeded all timeline expectations and is currently achieving up to 100 monthly installations, with zero disruption to daily operations.

Resources provided during implementation included:

- Dedicated program manager to support onboarding

- A welcome email with a comprehensive transition overview

- A customized landing page with bespoke downloadable educational resources including Job Aids, SOP’s, Container Education Videos, and Segregation Posters

- A QR code label on every container that links to video-based “how to use” tutorials, SOPs and waste safety posters

- In-service training and virtually scheduled webinar sessions for each site

Note: To save on installation costs, Daniels supported FMC in a seamless self-installation process. Empowered with a clear “how-to” road map, our local teams delivered both physical equipment and tailored onboarding resources to FMC clinics:

- Onboarding Checklist monitoring: Install phases, Servicing Plant, Site Locations, Start / Completion dates, Data Capture, Equipment Required, Current Vendor Notice & Last Service Date, Daniels First Service Date Introduction E-mail, Live Trainings, Daniels Equipment Drop-Off, Self-Install Date Review, Monthly Data Review, and Onboarding Review.

- Stock contingencies: Based on the number of sites and the needs of each location, we forecasted adequate stock requirements for each clinic. We also ensured additional contingency stock would be available at all local Daniels processing facilities.

- Equipment Delivery: Our local teams delivered all required equipment to each facility with clear step-by-step instructions for installation, ensuring containers were securely hung within NIOSH guidelines.

- Innovation: Daniels engineered a unique machine bracket adapter for dialysis machines that would fit the container mounting system from the previous vendor to simplify the de-installation / installation process.

The installation process reflects a service, system, and partnership approach that Daniels seeks to employ for all customers. By understanding FMC’s specific needs, Daniels was able to develop an installation process that not only worked for them, but provided innovations (like the machine bracket adapter) that created efficiencies that previously didn’t exist.

Daniels developed a dual-purpose reporting system that enables benchmarking internally across FMC sites nationally. The reporting dashboard includes: First service date, Annual Frequency Reductions, Container Fill Rates, and DIFOT scores (percent of services Delivered In Full and On Time). Daniels account management teams conduct quarterly business reviews with local facilities to ensure program goals are being met. Utilizing this reporting platform, Daniels has been able to:

- Optimize service frequencies to reduce costs & improve efficiency

- Monitor System-Wide Fill Rates

- Achieve 99.7% DIFOT score across all locations

- Share key metrics and KPIs across the business to ensure optimal service

KPIs include:

- Right sizing containers

- Reducing service frequency (lowering costs)

- Ensuring container utilization

- Delivering consistent & standardized education to ensure cost effectiveness

Since the implementation began, Daniels has been able to deliver on its word to drive significant cost savings and labor reductions across the system. The partnership has driven execution of the following:

- Rightsized containers, reduced service frequencies in over-serviced sites to eliminate wastage and lower costs, tracked container utilization site by site to monitor any locations that were falling outside expected parameters

- Reduced 4,450 waste pickups annually (and the significant associated costs) with right-fit scheduling per location

- Delivered standardized containers and education across the system, enabling system-wide benchmarking

- Ongoing reporting that benchmark average fill rates and waste volumes, providing critical data to drive change-management in any sites not conforming to best practice.

Let's Talk!

Your time is valuable, and we don’t want to play hard to get. You can either phone us directly on the details listed on our contact page, or feel free to fill out this short form and one of our team members will get back to you as quickly as possible.