How to Choose a Sharps Container

When we say, “don’t be basic,” we’re not trying to shame you for your love of Pumpkin-Spiced Lattes – they’re delicious! Rather, we’re trying to encourage you to look past the same, tired disposable sharps containers that have been available to healthcare for the past 2-3 decades. Vintage is not cute when it comes to safety solutions! It’s time to explore more modern sharps containers.

The needs of healthcare waste management are growing, as are the volumes of sharps waste generated every day. All used sharps waste generated in a healthcare setting that have been subjected to blood or bodily fluids, must be disposed of in a standards-approved sharps container.

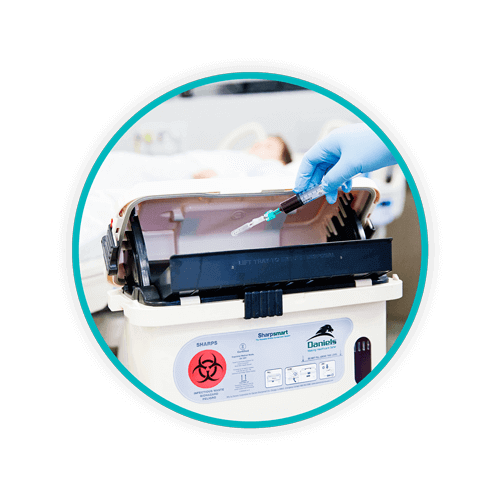

However, a common misconception is that sharps containers are used only for syringes. “Sharps” is the medical term for any sharp-pointed object that can cut, or pierce/penetrate the skin; this includes objects such as broken capillary tubes, culture slides, disposable scalpels and blades, and hypodermic needles and lancets.

In this blog, we’re going to walk you through all the factors to consider when choosing the safest sharps container for your facility – choose a modern solution that is totally not basic.

What type of Sharps Container should I use?

FDA Sharps Disposal Guidelines State:

- Used sharps can only be disposed of in a sharps container

- Sharps containers must be rigid, puncture-proof and sealed with a tight-fitting lid.

- It is recommended that a standards-approved sharps container is used for the collection of used sharps devices.

Disposable or Reusable?

In the United States, options for sharps containers are varied, but they are all based on one common alternative – a disposable sharps container or a reusable sharps container. In some healthcare settings, for example, a small dental clinic that generates a very low volume of sharps – a small half gallon disposable sharps container is preferenced because of the length of time that would pass for the container to be filled.

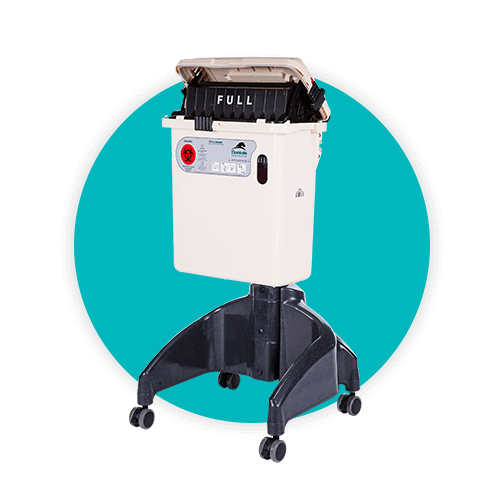

However, in large surgical clinics or hospitals where higher volumes of sharps are collected, a 2 or 4 gallon reusable container is the unspoken norm due to the amount of safety technology that is engineered into the design of a reusable sharps container.

While sharps waste volume and user-efficiency are deciding factors in choosing a suitable sharps container, another key consideration is environmental impact. In a disposable sharps container, 33% of the total waste volume is the plastic in the container itself! A recent study that was conducted at Loma Linda hospital in California1 showed that converting from disposable sharps containers to reusable sharps containers, prevented the manufacturing of 45,300+ containers, and ELIMINATED the landfill of plastic originating from disposable sharps containers. The year before Daniels Health rolled out its reusable Sharpsmart system, Loma Linda sent 35,925 disposable sharps containers to landfill.

*please note, if you utilize a disposable sharps container, this must be disposed of in an FDA approved medical waste container prior to transport

Learn more about our sharps container openings

Cabinet or Cabinet Free?

The emergence of inferior containers without adequate safety has bought with it a number of “work-arounds”, and one of these is exterior cabinetry to house the sharps container. One of the biggest safety and infection challenges that this brings, is the fact that cabinets can collect sharps directly through gaps between the container and cabinetry and injur the user upon opening, and secondly that the cabinets are rarely cleaned and act as a source of pathogen transfer.

Our recommendation is to choose a sharps container that is safe to be used independently of any further cabinetry, and if reusable, undergoes a washing process that achieves the highest levels of decontamination to ensure infection risks are eliminated.

UN TDG Certification

Daniels Sharpsmarts are the only sharps containers in the United States to have qualified for UN TDG (Transport of Dangerous Goods Certification), meaning that the containers are secure enough to be transported without outer packaging. Such certification doesn’t come easily.

For testing, the Sharpsmart container had to be filled with sharps, frozen (yes you’ve heard us right! put in a freezer to achieve iceblock status), and then the container had to be dropped from 6 feet onto a concrete slab in 6 orientations without splitting, cracking or leaking. This is pretty extreme testing, and whilst it doesn’t resemble a real-life scenario within a healthcare facility, it provides incredible assurance of the containers’ puncture-proof and spill-proof quality and peace-of-mind in safe cradle to grave transportation.

Why Infection Prevention is a high consideration in choosing a sharps container

Because needlesticks have the ability to carry infectious diseases through bloodborne pathogens, they are regarded as high occupational risk. With over 400 million blood draws performed each year, and over 60 bloodborne pathogens that can be transmitted through sharps injury exposure including Hepatitis B, C, HIV and malaria, sharps injury prevention should be one of the leading factors in selecting a suitable sharps container.

What waste stream does your used ‘sharp’ belong in?

Not all needlesticks can be deposited into a standard clinical sharps container; they must be segregated according to the substance contained within a sharp/syringe and/or contaminating the surface of the sharp object. Understand the difference between pharmaceutical sharps, chemotherapy sharps, and medical sharps by viewing our healthcare waste segregation poster here.

Location can sometimes be a factor in choosing a sharps container

The safety features of a sharps container must be suitable for the environment in which it is being used. For example, a sharps container located in a patient room must restrict hand access because it will be accessible to patients and visitors. At Daniels our Regular Sharpsmart range is designed for the patient setting. In non-public access areas such as pharmacies or surgical rooms where staff are adequately trained in safety procedures, it is more common to see open-access access containers use that permit quick deposition of sharps in fast-paced environments, and collection of large or bulky objects within surgery and dialysis. At Daniels, our Access-Plus Sharpsmart range is designed for secure non-public environments.

If you choose a wall-mounted sharps container, you may be wondering what the safesty heigh to mount the container is. The NIOSH recommended standard is 52-56 inches from the floor. We go into more detail here:

How high should you mount a sharps container?

What do the standards say, am I compliant?

Sharps containers are governed by FDA, DOT and OSHA laws; they have their own U.S. Standard, and fall under NIOSH’s governance in occupational safety recommendations. NIOSH is charged with identifying causes of work related injuries, evaluating new technologies and work practices, and identifying ways to control occupational hazards. In the evaluation of sharps containers, NIOSH provide needlestick injury prevention recommendations that fall into four key performance criteria – functionality, accessibility, visibility and accommodation. A full evaluation summary can be found here.

Serving the global healthcare industry for over 30 years, we’ve seen many trends come and go in the design and use of sharps containers. There are a few very clear no-no’s, but we thought we’d put together a few less obvious things to think about when you’re considering what sharps container is right for your facility:

- Choose a container that has a large horizontal vs small vertical drop zone for sharps stacking efficiency and volume optimization.

- When choosing a sharps container, ensure that you understand the true capacity of the container up to the fill line. By US regulations, every sharps container has a regulatory fill limit and sharps should not ever exceed this fill line.

- There are some basic passive safety features that every sharps container should have – restricted hand access, leakproof and puncture proof design, overfill protection, and secure safety closures.

Karen Daley, a nurse who was influential in the passing of the Needlestick Safety and Prevention Act signed by President Clinton, was a needlestick injury survivor. Karen’s injury was caused by an overfill sharps container, and one of her lasting observations as she has travelled the world speaking to victims of needlestick injuries is “not all safety devices are safe”, sharps injuries could be prevented by the use of safer sharps containers.

Understand the US Standards to make an educated choice

Based upon the guidelines set by OSHA, FDA, DOT, and NIOSH, we have put together a 139 item checklist that will help you better evaluate sharps containers as they relate to usability and compliance.

Or if you would like some human guidance, please don’t hesitate to reach out to one of our talented and experienced staff to talk through what sharps container options are right for you. E-mail us at hello@danielshealth.com or call us on 855 251 2655.

1 “Impact on life cycle carbon footprint of converting from disposable to reusable sharps containers in a large US hospital geographically distant from manufacturing and processing facilities” authored by Brett McPherson, Mihray Sharip and Terry Grimmond

Let's Talk!

Your time is valuable, and we don’t want to play hard to get. You can either phone us directly on the details listed on our contact page, or feel free to fill out this short form and one of our team members will get back to you as quickly as possible.